Discover Undercarriage Parts for Heavy Machinery

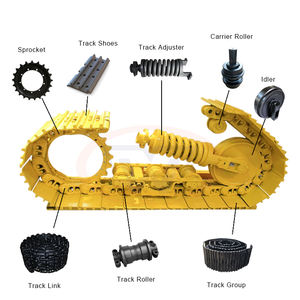

Comprehending the intricacies of undercarriage parts is vital for the optimal efficiency and durability of heavy machinery. From track shoes to sprockets, idlers, and rollers, each component plays an essential function in the functionality of the equipment.

Value of Undercarriage Components

The undercarriage components of heavy machinery play a crucial duty in ensuring the general efficiency and durability of the equipment. These parts, including tracks, rollers, chains, gears, and idlers, form the structure whereupon the device operates. A well-kept undercarriage not just provides stability and support to the heavy equipment however also contributes significantly to its operational efficiency and performance.

Among the key benefits of spending in premium undercarriage components is the reduction of downtime and maintenance prices. By using resilient elements that can hold up against the roughness of heavy-duty applications, drivers can lessen the demand for regular repair work and substitutes, therefore making best use of the device's uptime and general life expectancy.

Furthermore, correctly functioning undercarriage parts guarantee ideal weight maneuverability, traction, and distribution, permitting the hefty machinery to run smoothly even in difficult terrains. This reliability is vital for markets such as building, mining, and farming, where devices efficiency straight affects task timelines and profitability. To conclude, the relevance of undercarriage parts can not be overemphasized in preserving the performance and long life of heavy machinery.

Kinds Of Track Shoes

When thinking about the different sorts of track footwear for hefty machinery, it is important to evaluate their style and functionality in relationship to details operational requirements. Track footwear are crucial parts of the undercarriage system, offering traction, weight, and stability distribution for heavy machinery such as excavators, bulldozers, and crawler cranes.

One of the most common kinds of track footwear include:

** Grouser Shoes **: Including increased metal bars (grousers) along the footwear's surface, these track shoes supply boosted traction in difficult terrains like mud, snow, and loose crushed rock. undercarriage parts.

** Double Grouser Shoes **: Similar to grouser shoes but with an extra collection of grousers, these track footwear use even greater grip and security, making them ideal for incredibly rough terrains.

** Triple Grouser Shoes **: With 3 sets of grousers, these track footwear provide maximum traction and stability, making them ideal for the most requiring conditions.

Selecting the right sort of track footwear is crucial for enhancing the performance and long life of heavy equipment while making certain safety and security and efficiency during procedures.

Feature of Rollers and Idlers

Rollers and idlers play important duties in sustaining and guiding the track footwear of hefty equipment throughout operation. By avoiding too much slack or rigidity in the tracks, idlers contribute to the overall security and efficiency of the equipment.

In addition, rollers and idlers function with each other to keep the track shoes in placement, avoiding them from sliding or thwarting off during procedure. Appropriately functioning idlers and rollers are essential for guaranteeing the long life of the undercarriage system and taking full advantage of the device's performance. Routine upkeep and evaluation of these parts are important to recognize any indicators of wear or damage early on, protecting against expensive repair services and downtime over view time.

Role of Gears in Machinery

Maintenance Tips for Undercarriage Parts

Effective upkeep of undercarriage components is crucial for ensuring the durability and optimal performance of hefty machinery. Normal inspection of undercarriage parts such as track chains, rollers, idlers, sprockets, and track shoes is important to avoid pricey repair services and unanticipated break downs. One crucial upkeep idea is to maintain the undercarriage clean from debris, mud, and other contaminants that can increase wear and corrosion. It is also vital to make sure proper track tension to avoid premature wear on parts. Greasing the undercarriage parts at advised intervals aids to minimize rubbing and expand the lifespan of the components. Keeping track of for any kind of uncommon noises, vibrations, or modifications in machine performance can indicate prospective issues with the undercarriage that need immediate interest. By following these maintenance tips faithfully, hefty machinery drivers can decrease downtime, decrease operating expenses, and make best use of the performance of their tools.

Final Thought

To conclude, the undercarriage parts of hefty machinery play a crucial duty in guaranteeing the smooth functioning and durability of the tools. More hints Recognizing the significance of track footwear, sprockets, idlers, and rollers, in addition to carrying out proper maintenance methods, can substantially impact the general efficiency and effectiveness of the machinery (undercarriage parts). Routine assessment and timely replacement of worn-out components are view website important in making best use of the lifespan and performance of heavy equipment

Rollers and idlers play essential duties in supporting and leading the track footwear of hefty machinery throughout operation.In heavy machinery, gears offer an essential function in moving power from the engine to the tracks, enabling the tools to move successfully and properly. These elements are connected to the axles or final drives of the equipment and work in conjunction with the tracks to thrust the tools ahead or backward. Regular evaluation of undercarriage components such as track chains, rollers, idlers, gears, and track footwear is crucial to stop expensive repairs and unexpected breakdowns. Recognizing the relevance of track shoes, idlers, gears, and rollers, as well as implementing correct maintenance practices, can greatly affect the general performance and effectiveness of the machinery.

Comments on “Increase Productivity: Just How Upgrading Undercarriage Parts Can Improve Efficiency”